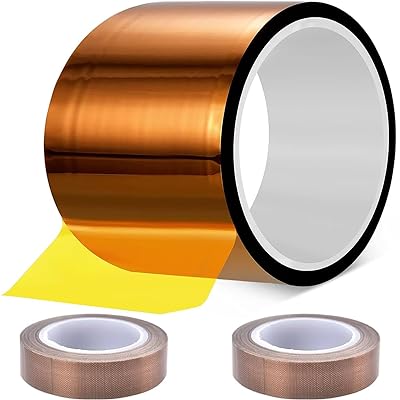

Single Conductive Copper Foil Adhesive Tape

Single Conductive Copper Foil Adhesive Tape is a high-performance material designed for precision electronic applications. It features a copper foil layer (0.035mm thick) bonded with a conductive acrylic pressure-sensitive adhesive (0.040mm thick), achieving a total thickness of 0.075mm and ultra-low resistivity of 0.004Ω, ensuring efficient electrical conductivity. The adhesive’s polypropylene base enables quick bonding to surfaces like sample stages or circuit boards, while its temperature resistance (up to 150°C intermittently) suits demanding environments such as PCB assembly and mobile device shielding.

Manufactured by Fubang Tape Co., Ltd (ISO 9001/14001 certified), this tape is tailored for industries including consumer electronics, automotive sensors, and LCD modules. Its soft, easy-to-cut design simplifies customization for complex layouts, and the smooth surface enhances contact reliability in EMI shielding and grounding applications. The company’s state-of-the-art facility and focus on innovation ensure consistent quality, with options for bulk orders (100+ rolls) and export-friendly packaging.

Ideal for engineers requiring rapid prototyping or mass production, this tape combines cost-effectiveness (FOB price: $0.50–2.50/roll) with technical precision, backed by over a decade of expertise in conductive material R&D

Features

Conductive Adhesive Layer & Low Resistance

The tape uses conductive pressure-sensitive acrylic adhesive with embedded conductive particles, enabling low-resistance bonding between the copper foil and substrates. The resistivity is as low as 0.005Ω (tested per Mil-STD-202 Method 303), ideal for scenarios requiring rapid electrical pathways, such as PCB shielding or sensor grounding.

Flexible Copper Foil Backing

The backing consists of 1-ounce rolled copper foil (0.04mm thick), with a total thickness of 0.066mm. This design ensures flexibility for conforming to irregular surfaces while retaining solderability for post-application processes.

Flame Retardancy & Eco-Certifications

Compliant with UL510 flame-retardant standards (Certification No.: OANZ2/E17385) and RoHS Directive (2002/95/EC), the tape meets safety and environmental requirements for use in electronic devices.

Wide Temperature Range & Strong Adhesion

Operates reliably in temperatures ranging from **-40°C to 130°C**, with an adhesion strength of 35 oz/inch (ASTM D3330 tested), ensuring durability in high-temperature environments.

High Shielding Effectiveness

Provides 85dB shielding efficiency (ASTM D-4935 tested) within the 1MHz–2GHz frequency range, making it suitable for EMI/RFI shielding, cable wrapping, and sealing gaps in shielded enclosures.

Application

Consumer Electronics

Smartphones/Tablets: EMI shielding for PCBs, touchscreen grounding, and battery contact fixation.

Laptops: Internal cable shielding and conductive adhesion for heat dissipation modules to reduce signal interference.

Wearables: Ultra-thin design for miniaturized sensors (e.g., smartwatch heart rate monitors).

Automotive Electronics

In-Vehicle Displays: Flexible adhesion to curved screen edges for anti-static protection.

Battery Management Systems (BMS): HV cable shielding to enhance EV battery safety.

Sensor Modules: Secures ABS/ECU sensors, withstands high-temperature engine compartment environments (-40°C to 130°C).

Telecommunication Equipment

5G Base Stations: High-frequency signal shielding to minimize RF interference (85dB efficiency at 1MHz–2GHz).

Fiber Optic Terminals: Conductive grounding to prevent lightning surge damage.

Industrial & Medical

Industrial Robots: Anti-interference wrapping for servo motor cables, improving control precision.

Medical Imaging Devices: Conductive connections in MRI/CT scanners, compliant with RoHS safety standards.

New Energy & Aerospace

PV Inverters: Enhances conductivity and heat dissipation by adhering copper foil to heat sinks.

Satellite Communication Modules: Lightweight shielding materials for spacecraft in extreme thermal conditions.