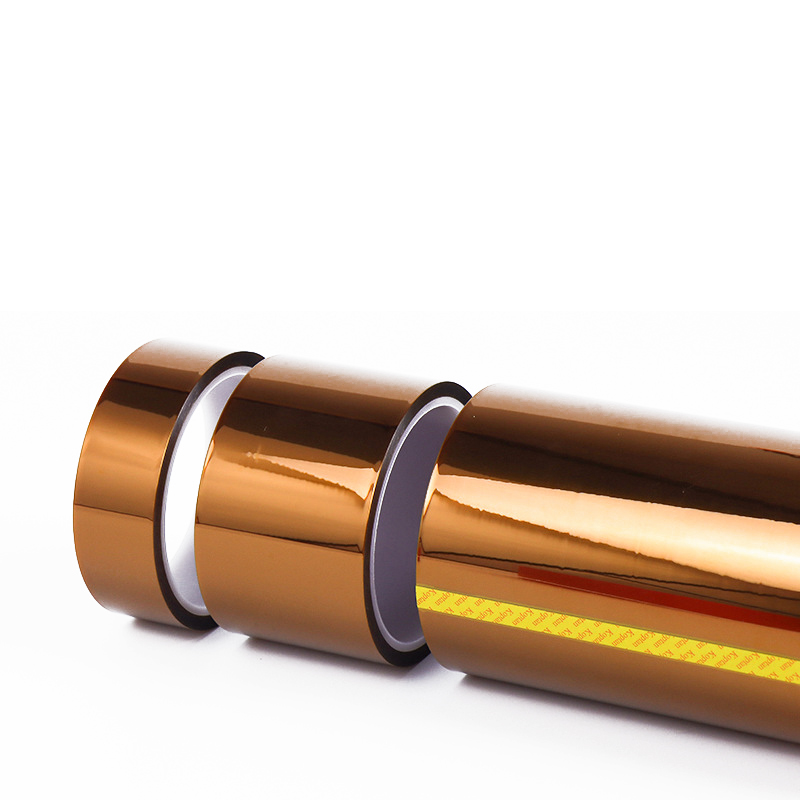

What is Polyimide Adhesive Tape/ PI?

Polyimide Adhesive Tape, also known as PI tape, is a high temperature resistant tape widely used in electronics, aerospace, automotive and other industries. It uses polyimide film as the base material and is coated with high-temperature resistant adhesive, which has excellent heat resistance, insulation and chemical stability.

As a high-performance tape, Polyimide Adhesive Tape has excellent high temperature resistance, insulation and chemical stability, and is suitable for the protection and insulation of electronic components in various high temperature environments. When you choose Polyimide Adhesive Tape, you will get a reliable, efficient and safe solution to protect your electronic equipment and components and ensure their stable and reliable operation.

High temperature resistance: PI tape has excellent high temperature resistance and can maintain stability in extreme temperatures from -269°C to 400°C. This makes it ideal for handling electronic components in high temperature environments.

Excellent insulation: Made of polyimide film, PI tape has excellent insulation properties, which can effectively prevent short circuits or leakage between electrical equipment and electronic components, ensuring the safe and stable operation of equipment.

Chemical stability: PI tape has good chemical stability and can resist the erosion of a variety of chemical substances, including solvents, acids and alkalis, etc., and is not susceptible to corrosion or damage, extending its service life.

Excellent mechanical properties: PI tape has excellent mechanical strength and wear resistance, is not susceptible to stretching or tearing, and can maintain stability under various harsh conditions.

Easy peelability: PI tape is coated with a special adhesive, which has good peelability and can be easily peeled off when needed without leaving any residue or damaging the surface.

Comparative Analysis: Polyimide Adhesive Tape vs. Common Tape Materials

In the realm of adhesive tapes, various materials are utilized to meet different application needs. Among these materials, Polyimide (PI) adhesive tape stands out for its exceptional performance in high-temperature environments, insulation properties, and chemical stability. In this article, we will compare Polyimide Adhesive Tape with other common tape materials such as PVC (Polyvinyl Chloride) and PET (Polyethylene Terephthalate) in terms of their high-temperature resistance, insulation capabilities, and chemical stability.

1. High-Temperature Resistance:

Polyimide Adhesive Tape (PI): Polyimide adhesive tape is renowned for its outstanding resistance to high temperatures. It can withstand extreme temperature ranges from -269°C to 400°C without compromising its adhesive properties or physical integrity. This makes it ideal for applications in industries such as aerospace, automotive, and electronics, where exposure to elevated temperatures is common.

PVC (Polyvinyl Chloride) Tape: PVC tape exhibits moderate temperature resistance, typically ranging from -10°C to 80°C. While it can withstand relatively high temperatures compared to some other materials, it is not suitable for use in extreme heat environments.

PET (Polyethylene Terephthalate) Tape: PET tape offers good temperature resistance, withstanding temperatures up to approximately 150°C. While it can handle moderately high temperatures, it may not be suitable for prolonged exposure to extreme heat.

2. Insulation Properties:

Polyimide Adhesive Tape (PI): Polyimide tape is highly regarded for its excellent insulation properties. It provides effective electrical insulation, preventing short circuits or electrical leakage between components. This makes it a preferred choice for applications in the electronics industry, such as insulating wires, circuits, and electronic components.

PVC (Polyvinyl Chloride) Tape: PVC tape also offers good electrical insulation properties, making it suitable for a range of electrical applications. However, it may not provide the same level of insulation performance as Polyimide tape in high-temperature environments.

PET (Polyethylene Terephthalate) Tape: PET tape provides moderate electrical insulation properties, but its insulation performance may degrade at higher temperatures. It is commonly used in applications where high-temperature resistance is not a primary concern.

3. Chemical Stability:

Polyimide Adhesive Tape (PI): Polyimide tape demonstrates excellent chemical stability, resisting the effects of various chemicals, solvents, and acids. This makes it suitable for use in harsh chemical environments without deteriorating or losing its adhesive properties.

PVC (Polyvinyl Chloride) Tape: PVC tape exhibits good resistance to many chemicals and solvents. However, it may degrade or react with certain chemicals over time, leading to a loss of adhesive strength or physical integrity.

PET (Polyethylene Terephthalate) Tape: PET tape offers moderate chemical resistance but may be susceptible to degradation when exposed to certain chemicals or solvents. It is important to consider the specific chemical compatibility requirements of the application when selecting PET tape.

In conclusion, Polyimide Adhesive Tape (PI) stands out as a superior choice for applications requiring high-temperature resistance, excellent insulation properties, and chemical stability. While PVC and PET tapes have their own advantages and applications, they may not offer the same level of performance in extreme conditions. When selecting a tape material, it is essential to consider the specific requirements of the application and choose the most suitable option based on factors such as temperature range, insulation needs, and chemical compatibility.

High-Performance Polyimide Adhesive Tape (PI) for Extreme Conditions

Polyimide Adhesive Tape (PI) is a high-performance tape designed for demanding applications. With excellent thermal resistance, electrical insulation, and chemical stability, it is ideal for use in electronics, aerospace, and industrial settings. This tape offers reliable adhesion at high temperatures and is resistant to abrasion and solvents, making it a versatile choice for various applications.

FAQ about Polyimide Adhesive Tape/ PI

What are the temperature limits of Polyimide Adhesive Tape (PI)?

Polyimide Adhesive Tape (PI) can withstand extreme temperatures ranging from -269°C to 400°C, making it suitable for applications where exposure to high heat is common, such as soldering, circuit board assembly, and aerospace components.

Is Polyimide Adhesive Tape (PI) suitable for electrical insulation purposes?

Yes, Polyimide Adhesive Tape (PI) is widely used for electrical insulation due to its excellent dielectric strength and insulation properties. It effectively insulates wires, cables, and electronic components, preventing short circuits and electrical hazards.

Can Polyimide Adhesive Tape (PI) be used in harsh chemical environments?

Yes, Polyimide Adhesive Tape (PI) exhibits excellent chemical resistance and can withstand exposure to many chemicals, solvents, and acids without deteriorating or losing its adhesive properties. It is commonly used in chemical processing and laboratory applications.

Is Polyimide Adhesive Tape (PI) easy to remove after use?

Yes, Polyimide Adhesive Tape (PI) is designed to be easily removable without leaving residue or damaging surfaces. It offers good peel strength while allowing for clean removal, making it ideal for temporary masking or protection applications.

Can Polyimide Adhesive Tape (PI) be customized for specific applications?

Yes, Polyimide Adhesive Tape (PI) can be customized in terms of width, length, thickness, and adhesive strength to meet the specific requirements of different applications. Custom printing options for logos or labels are also available.